2013 March 19: Install the right cylinder head

Created:

Updated:

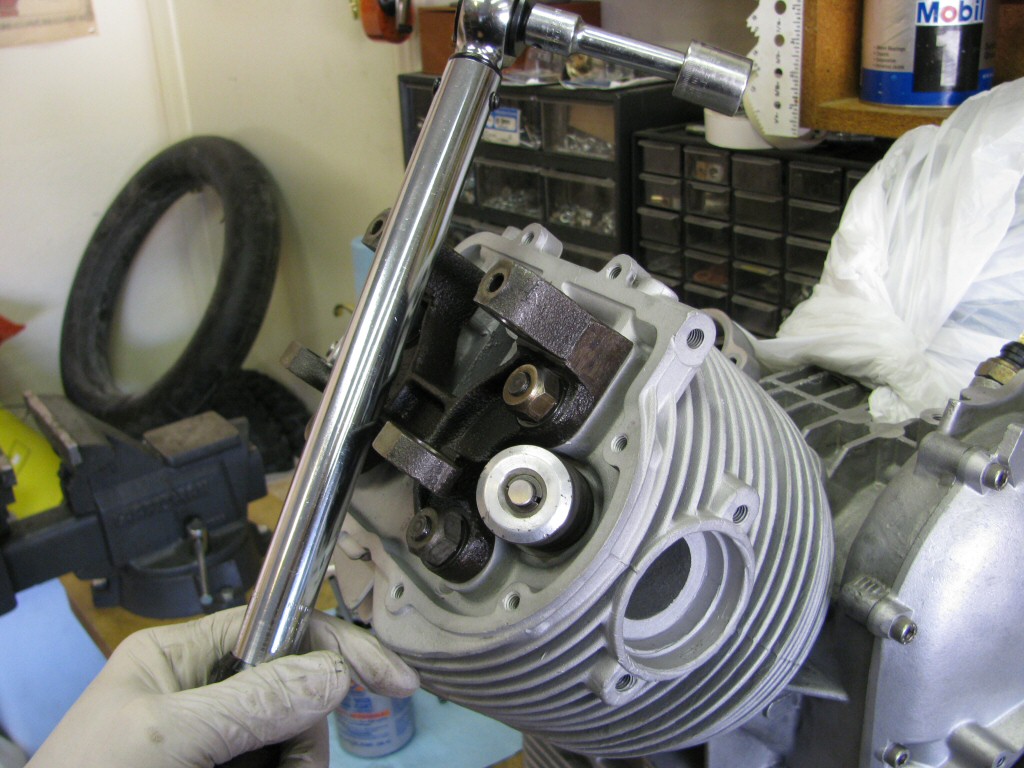

Photo courtesy of Gregory Bender.

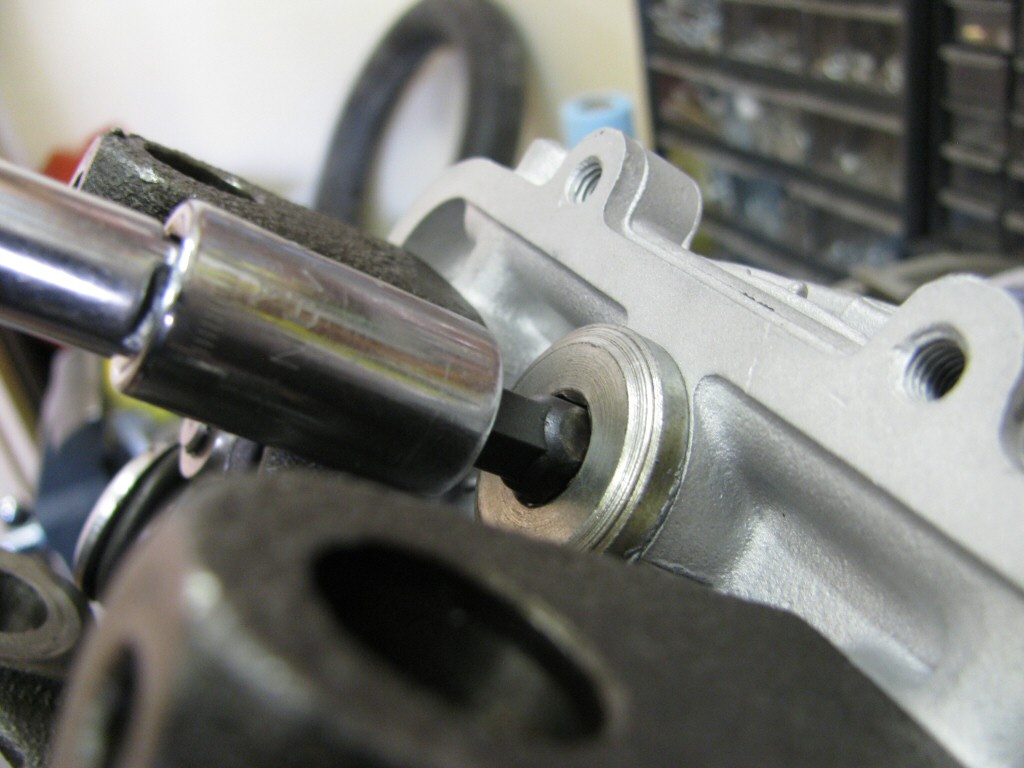

Photo courtesy of Gregory Bender.

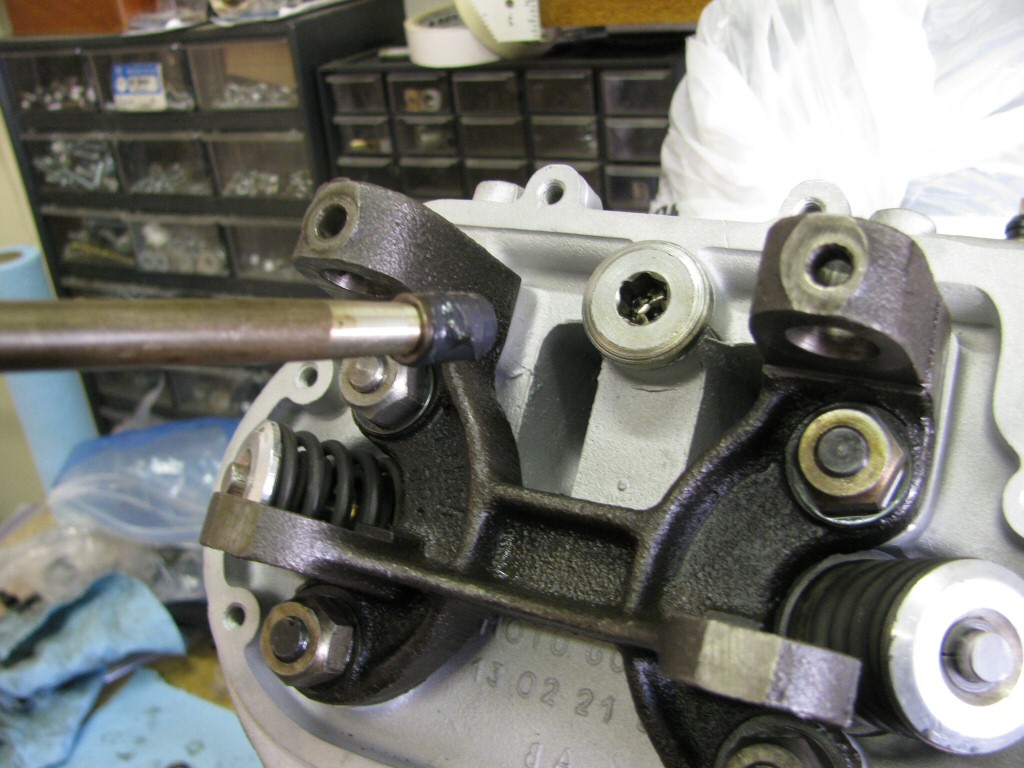

Photo courtesy of Gregory Bender.

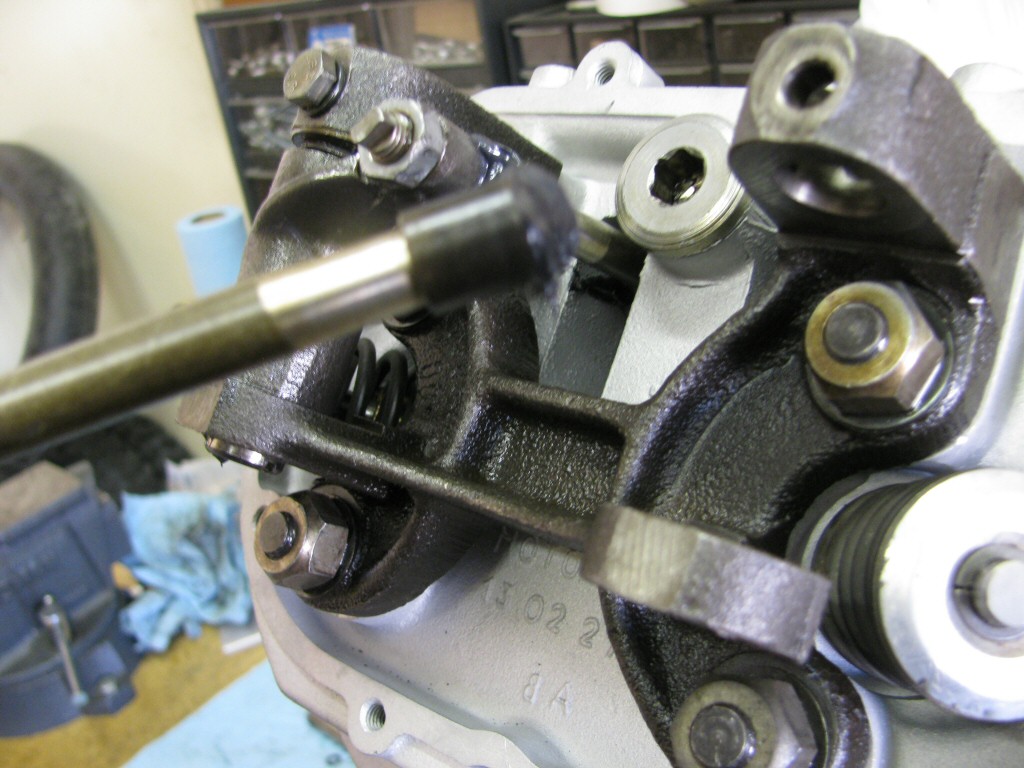

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

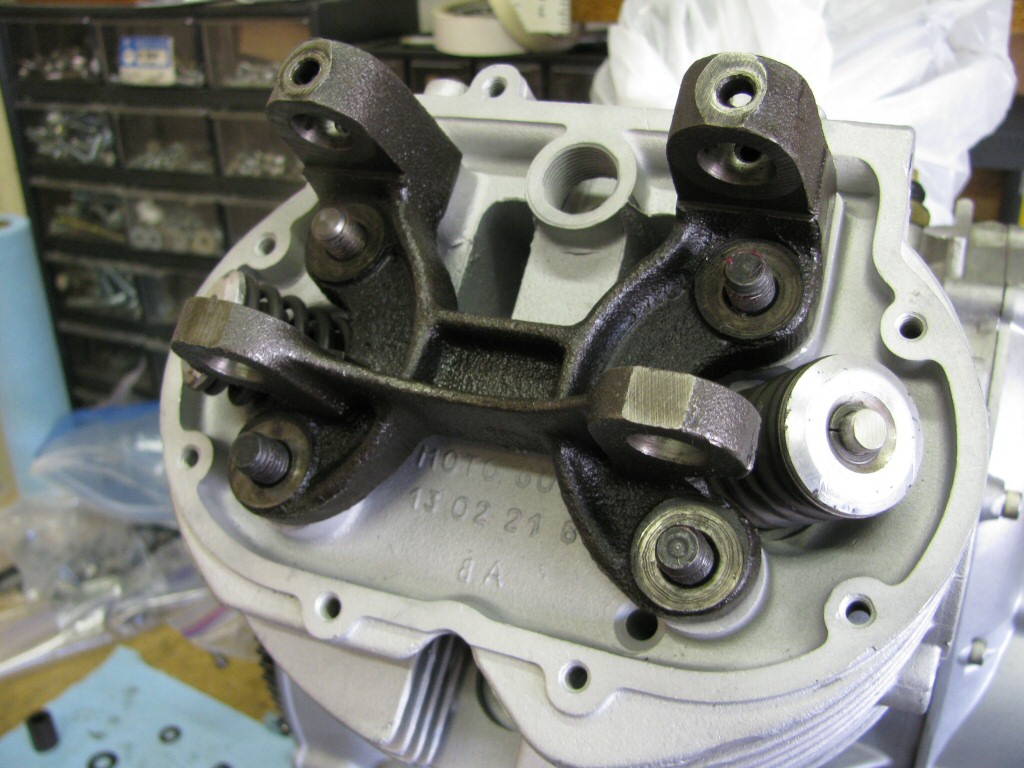

6 o'clockstud.

Photo courtesy of Gregory Bender.

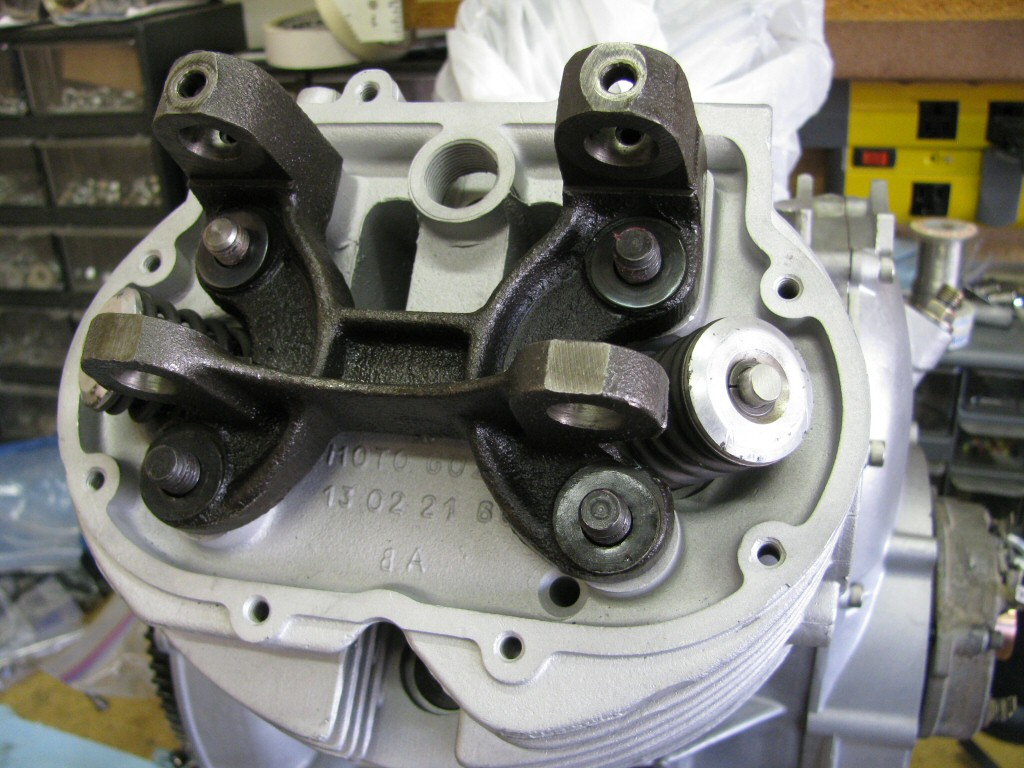

12 o'clockstud.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

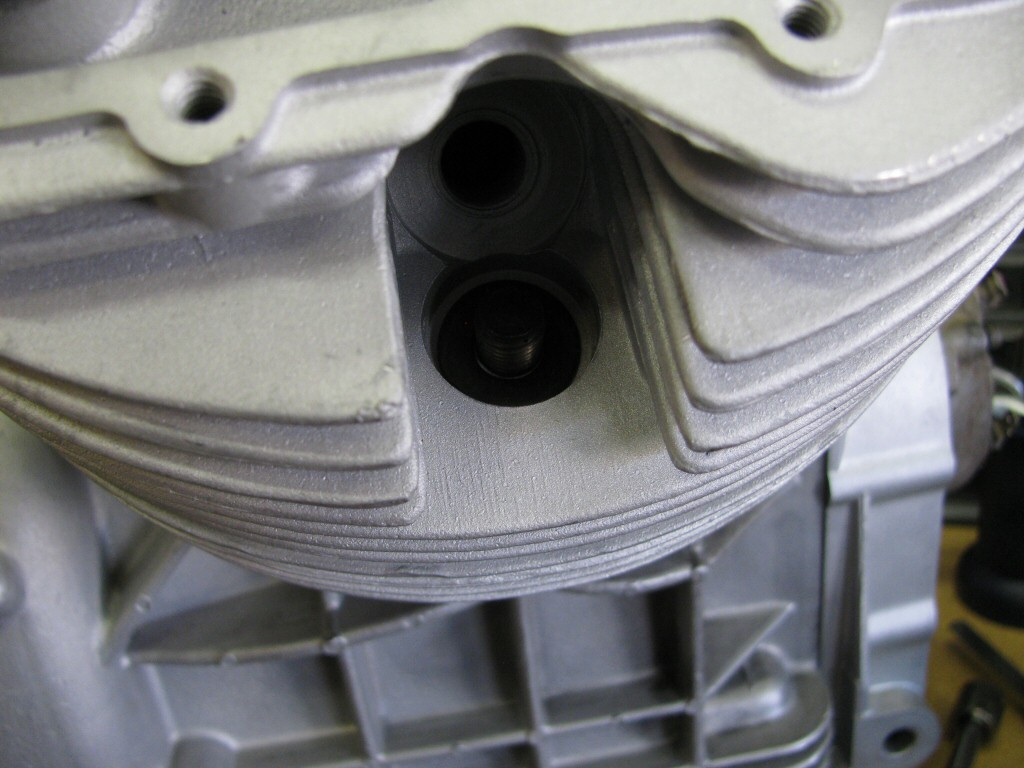

12 o'clockand

6 o'clocknuts.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

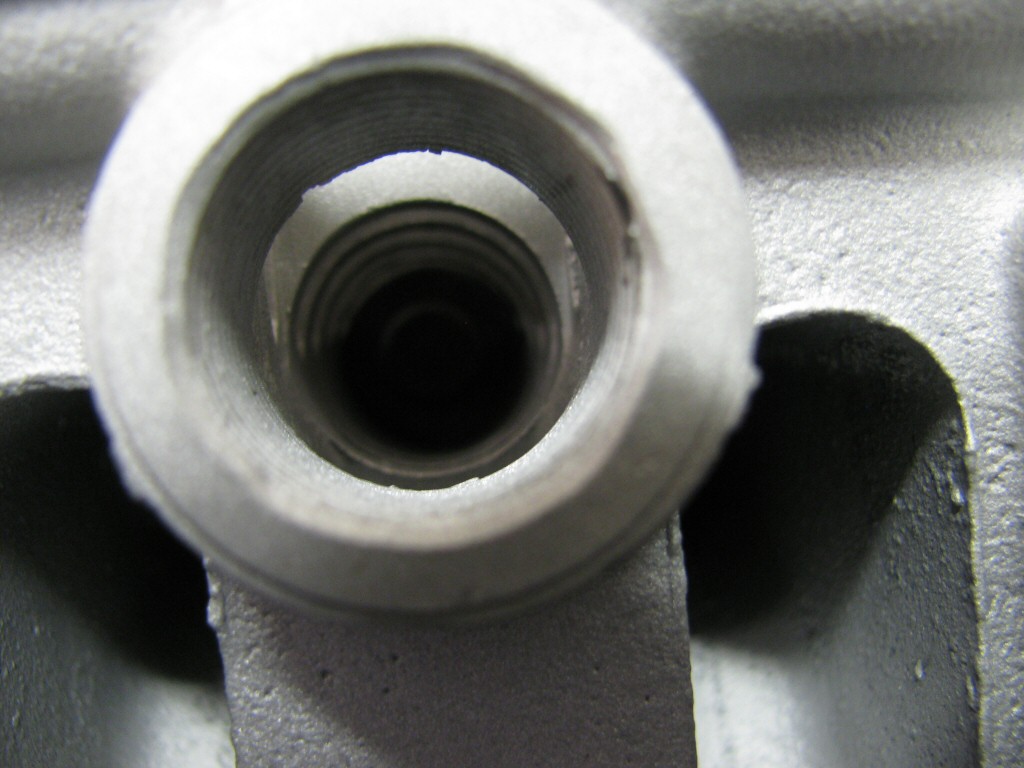

12 o'clocknut access hole. Again, I apply anti-seize to the threads.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.